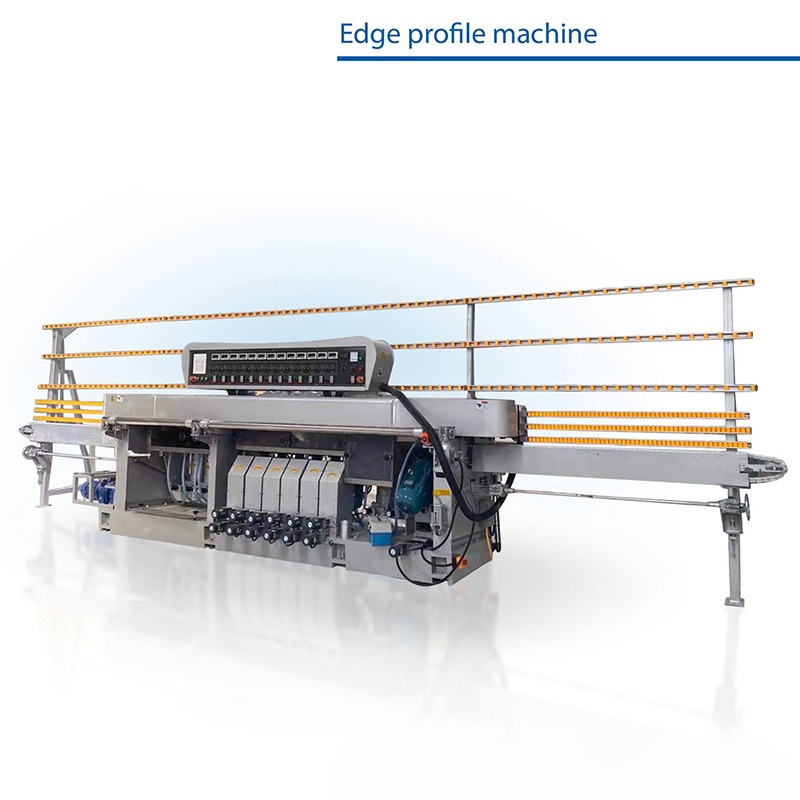

The Double Side Edging Chamfering Machine is a highly efficient and versatile machine that is designed to provide precise and accurate chamfering and edging of glass panels. This machine is widely used in the glass processing industry for the production of high-quality glass products such as mirrors, tempered glass, laminated glass, and more.

This machine is used for grinding the flat glass of bilateral straight flat edge, including rough grinding, fine grinding, upper chamfering, lower chamfering, upper chamfering polishing, lower chamfering polishing, flat edge three polishing.

The grinding head motor seat adopts double linear guide rail and double ball screw drive to achieve stable moving speed, eliminate moving clearance, and reduce drag and friction. The set processing parameters can complete at one time.

Competitive Advantage:

1. Main transmission shaft is placed on the upper of machine, which extends main shaft life and easy to replace

synchronous belt.

2. The design of catch pawl ensures the high precision of glass diagonal.

3. Unique design of grinding head that improves the running accuracy and impact resistance of the grinding head

and prolongs the service life of the motor.

3. The design of three-point lifting pillar ensures perfect straightness.

4. The upper design of down chamfering motor ensures the completeness of sliding table, and keeps machine

structure more stable.

5. Automatic lubricating system extends equipment life.

Features:

(1) High-precision grinding head, tablet pressing and glass conveying system, with higher grinding efficiency and more stable effect.

(2) The original glass precision positioning system, its structure and positioning action improve the diagonal precision of the glass.

(3) The pressure beam and the upper chamfering seat are lifted and lowered synchronously, which makes the operation easier.

(4) Integral box and continuous group of movable side sliders, with good rigidity and strong stability.

(5) The top-mounted drive shaft prevents the drive shaft from being stuck when opening and closing, and it is convenient to replace the belt.

(6) The large open grinding wheel water tank is convenient for adjusting the machine and replacing the waterproof cover (embedded fixed waterproof cover).

(7) The ammeter is close to the handwheel of the grinding head motor, which is convenient for observing the current and adjusting the motor back and forth.

(8) The 45-degree upward chamfering adjustment handwheel is convenient for adjusting the downward chamfering grinding head motor.

(9) Opening and closing, lifting, synchronous belt drive and glass thickness detection system to protect the safety of the machine.

(10) The whole machine has excellent waterproof performance.

(11) The structure of the machine is simple, the workmanship is fine and generous, and the vision is wide and comfortable.

About GLS

For 30 years GLS Stone Group has focused making the highest quality stone equipment for all areas of stone production to create real value to our customers through GLS Stone Machines.

In the early 90s GLS Stone Group began introducing the newest stone equipment technologies to the United States. Since then we have kept up with the latest innovations in the industry integrating with the newest modifications on all models of GLS Stone Machines